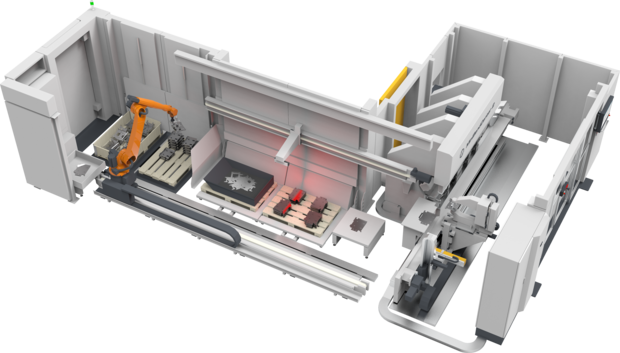

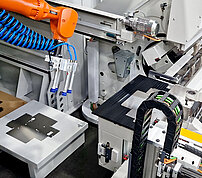

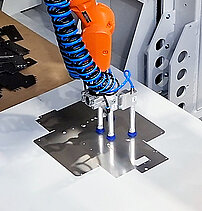

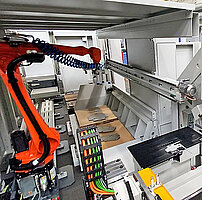

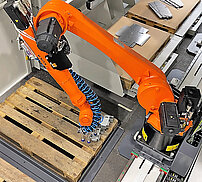

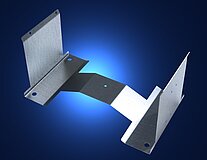

A camera system enables the intelligent loading robot to recognize the position of the blanks of a bulk material quantity on a pallet. The software calculates which blanks form the top layer and which parts the robot can access. The robot then picks up one of the available blanks and feeds it to the MiniBendCenter 2.

Of course, the robot can also grip the blanks in stacks. The blanks do not have to lie exactly on top of each other. And the best thing is that the robot does not need to be taught or programmed. Simply start a bending program and the machine does the rest.

- No programming or teaching necessary

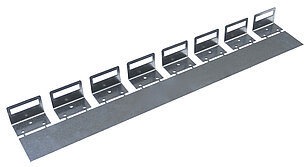

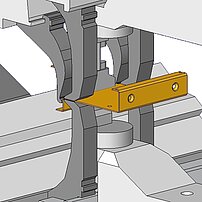

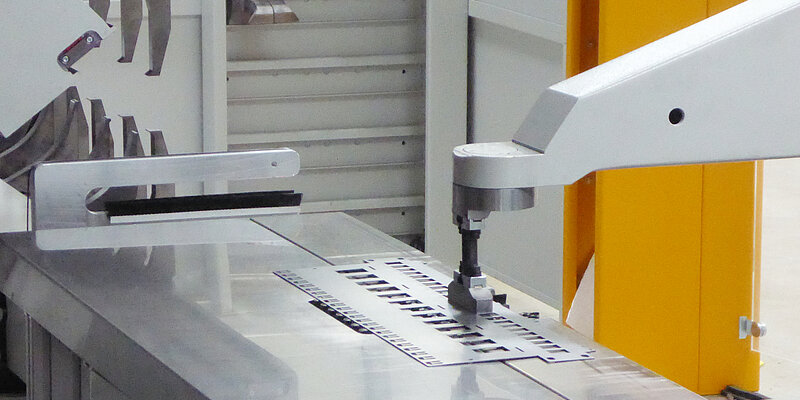

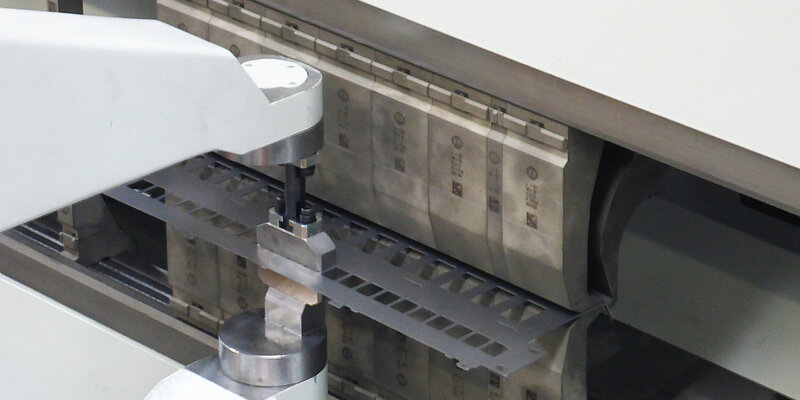

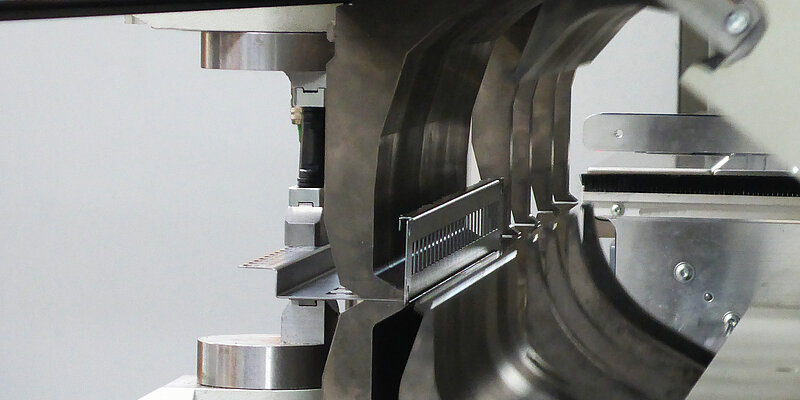

- Robot grips the blank and feeds it to the bending center

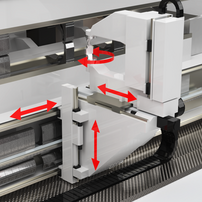

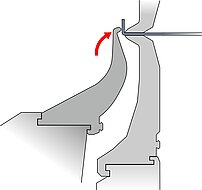

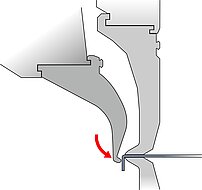

- Parts that are upside down are sorted out