UpDownCenter-2: 600mm deep electrical en...

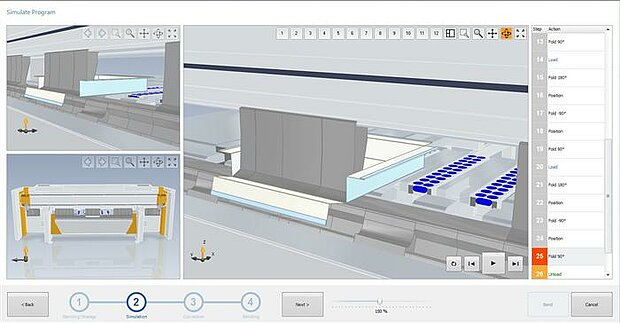

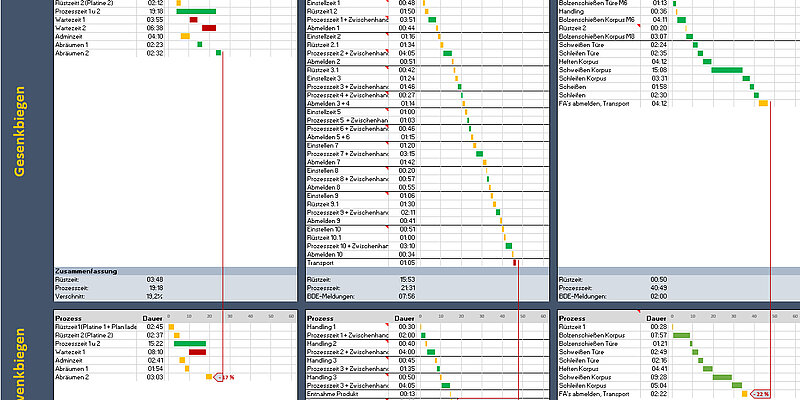

UpDownCenter-2: Programming and Bending

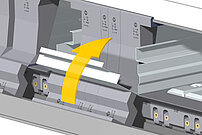

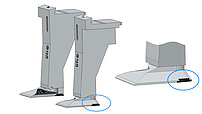

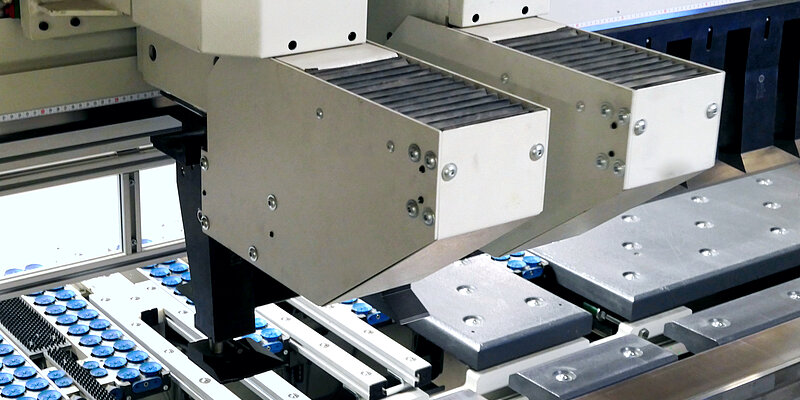

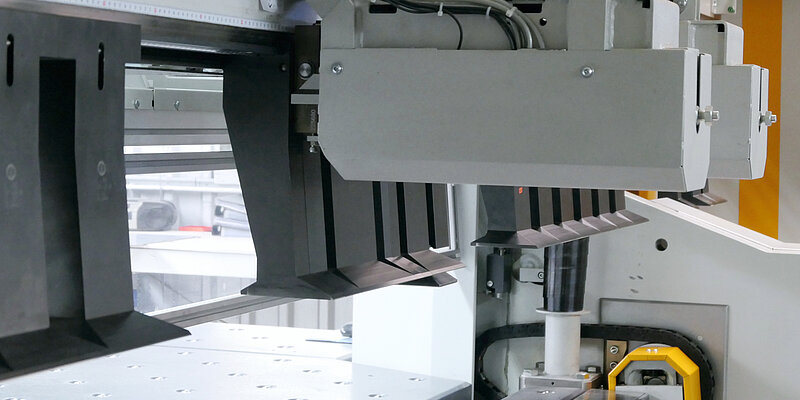

UpDownCenter-2: Drawer with UpDownTools

RAS UpDownCenter-2: Soundproof enclosure...

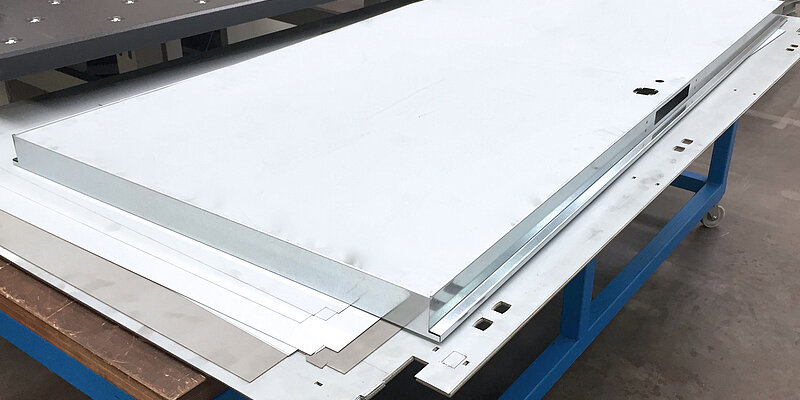

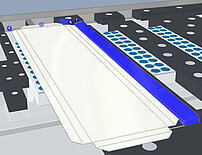

UpDownCenter-2: Kit Production of aircon...

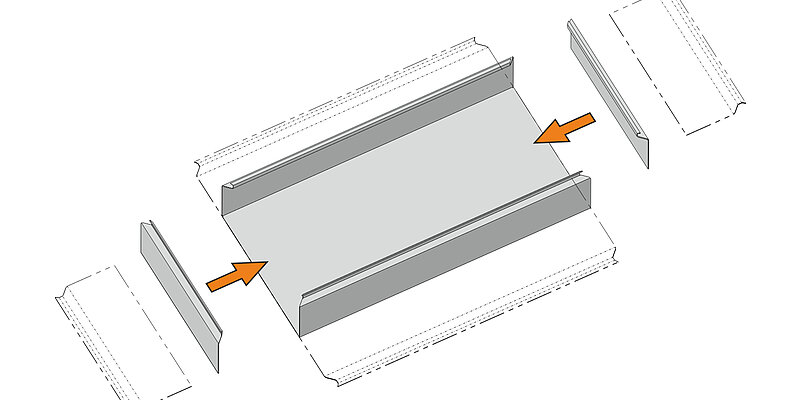

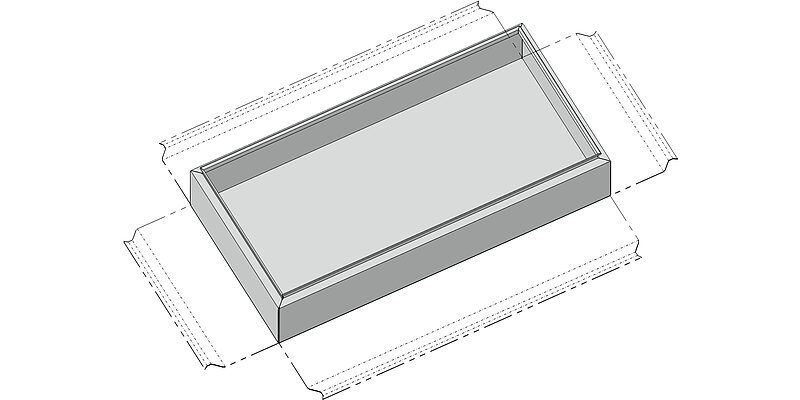

UpDownCenter-2: Air conditioning unit co...

UpDownCenter-2: Folding electrical cabin...

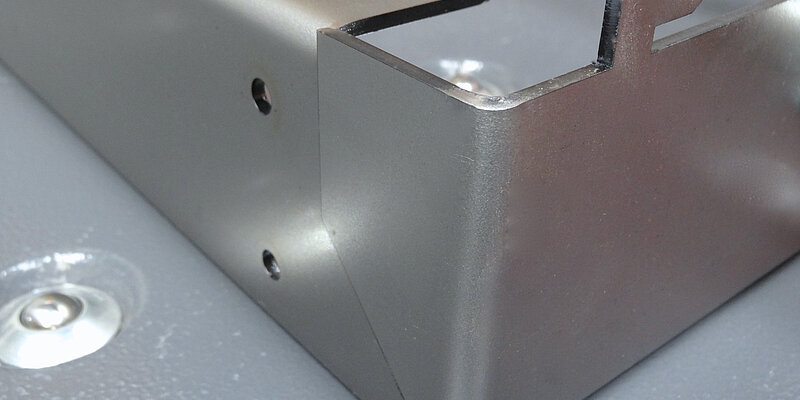

UpDownCenter-2 bends small electrical ca...

Panel bender UpDownCenter RAS 78.43-2

UpDownCenter: 400 mm electrical cabinet ...

UpDownCenter: Folding Safety Doors

UpDownCenter-2: 400 mm deep electrical c...

UpDownCenter: Rößler GmbH

UpDownCenter: Soundproof enclosures

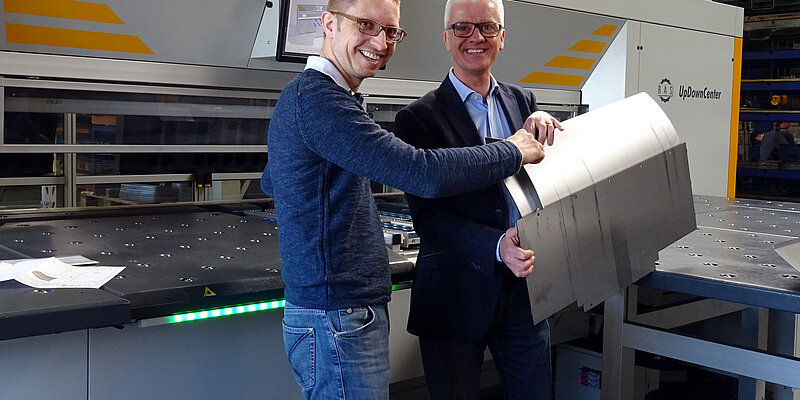

UpDownCenter: von Arb SAS AG, Switzerlan...

UpDownCenter bends medical furniture

RAS UpDownCenter: Side panel with large ...

RAS UpDownCenter: Cabinet door with rad...

UpDownCenter-2: Electrical cabinet with ...

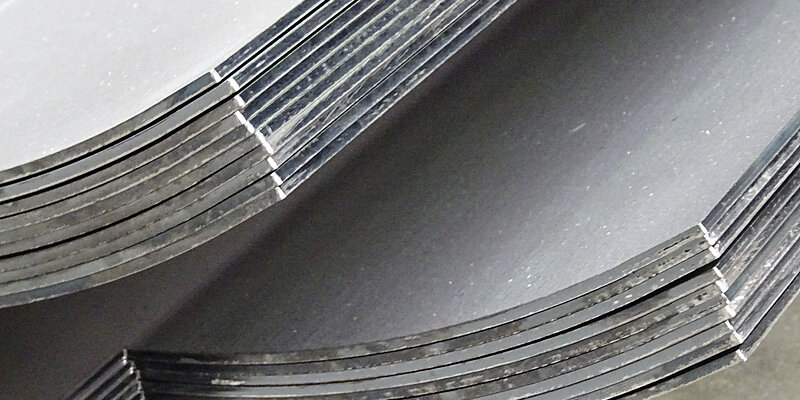

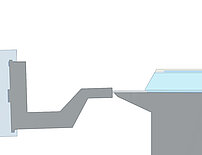

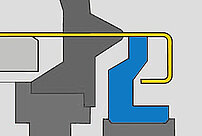

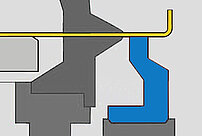

RAS metal folding: Bending radii without...

UpDownCenter: Electrical cabinets

UpDownCenter: Fire hose cabinets

RAS UpDownCenter: Folding Center

UpDownCenter: Aluminum composite facade ...

UpDownCenter: Metal facades

UpDownCenter: Refrigerated counter

UpDownCenter: Machine covers with radii

UpDownCenter: Facade cassette with hook

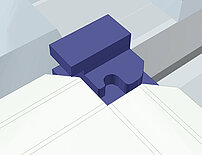

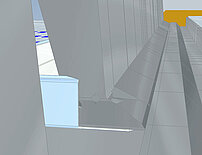

UpDownCenter-2: Bending radii of any siz...

Frea & Frea: Metal facades

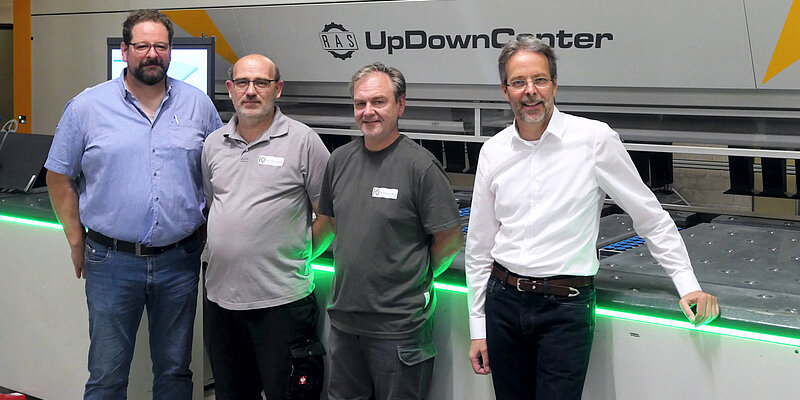

RAS UpDownCenter-2 at Tamellin (Italy)

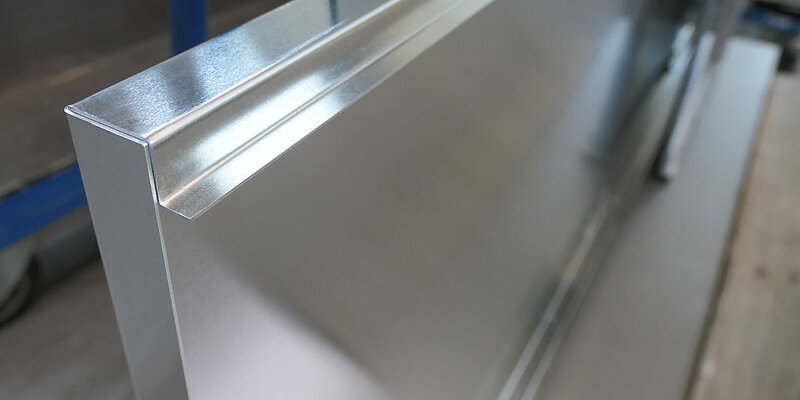

UpDownCenter-2: Bending large panels

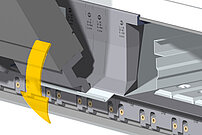

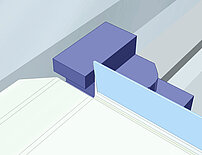

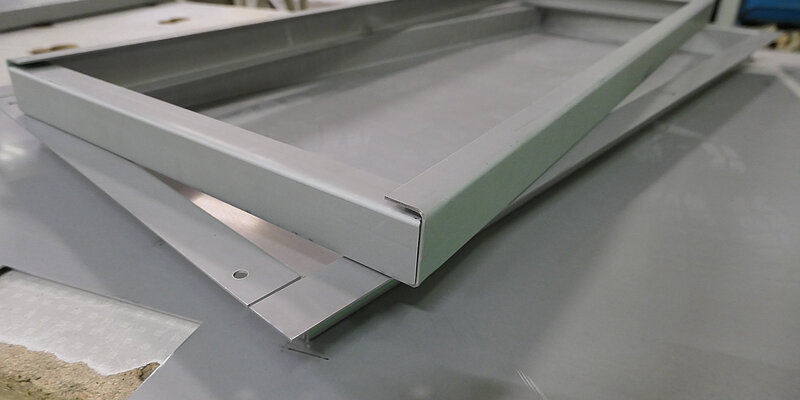

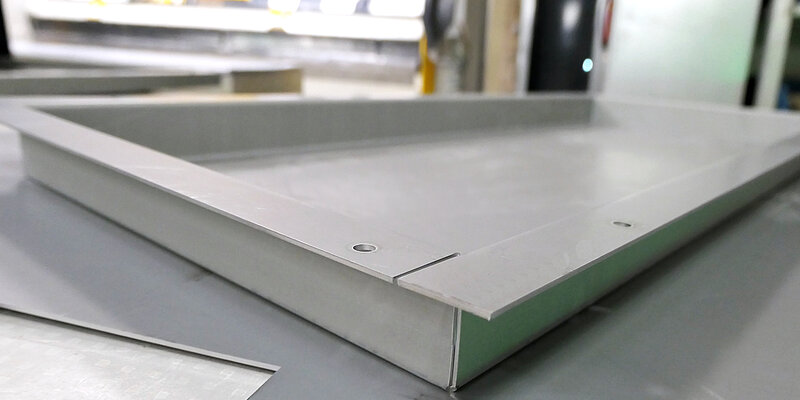

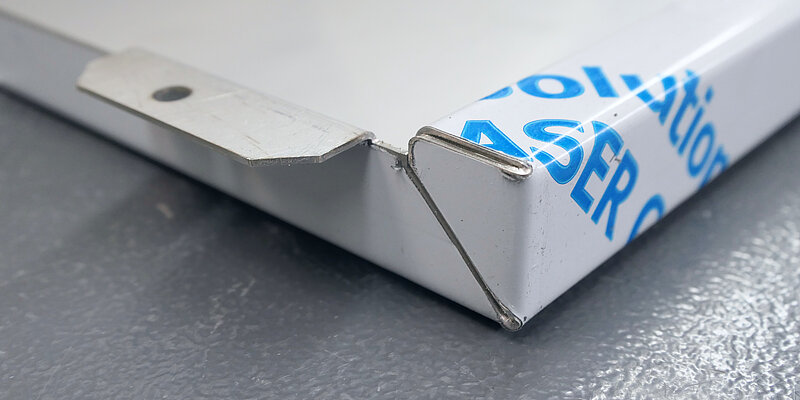

UpDownCenter-2: Hemming with tool heel

![[Translate to English:] Entnehmen eines automatisch gebogenen Metallteils mit Radius](/fileadmin/_processed_/5/0/csm_Kaschwig_3D-Ecke-entnehmen_2055824f32.jpg)

![[Translate to English:] Gedämmte Metallkassetten für Wände von Schallschutzkabinen](/fileadmin/_processed_/b/e/csm_Kaschwig_Daemmelemente_865447b9a5.jpg)

![[Translate to English:] Die Platine bleibt immer auf dem Tisch liegen. "Die Zeiten mit Rückenschmerzen sind vorbei", bestätigt Maschinenbediener Fabian Arn.](/fileadmin/_processed_/0/7/csm_DSC00352_3975cd0270.jpg)